are bearings they permit rotation between parts, but they

are designed to support a high axial (along the same line as an axis

(coaxial) or centerline) load

while doing this.

Thrust bearings come in several varieties.

-

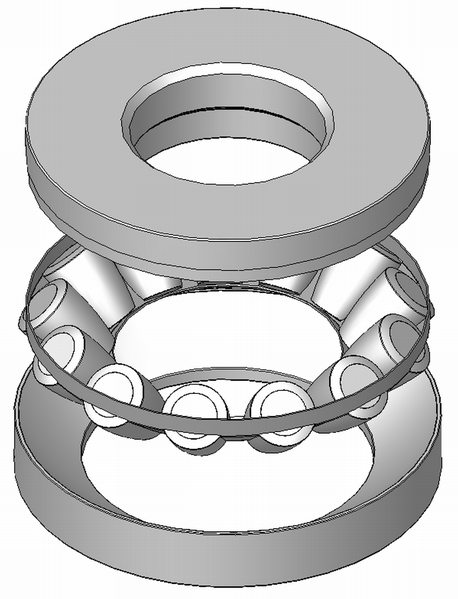

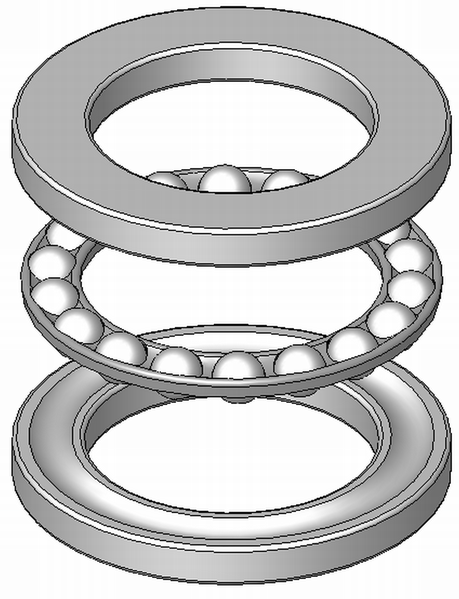

Ball thrust bearings, comprised of

ball bearings supported in a ring, can be used in low thrust

applications where there is little radial (line drawn along a vector)

load.

-

Tapered roller bearings consist of small tapered rollers arranged

so that their axes all converge at a point on the axis of the bearing. The

length of the roller and the diameter of the wide and the narrow ends need

to be carefully calculated to provide the correct taper so that each end

of the roller rolls smoothly on the bearing face without skidding. These

are the type most commonly used in automotive applications, where they are

used in pairs to accommodate axial thrust in either direction, as well as

radial loads. They can support rather larger thrust loads than the ball

type due to the larger contact area, but are more expensive to

manufacture.

They are commonly used in automotive and marine and

aerospace applications. Thrust bearings are necessary in cars because

the forward gears in modern car

gearboxes

use

helical gears which, while aiding in smoothness and noise reduction,

cause axial forces that need to be dealt with.

1.

2.

.