is an engine driven directly by the expansion of

combustion gases, rather than by an

externally produced medium, such as steam. Basic versions of the internal

combustion engine are: gasoline engine and gas engine (spark

ignition), diesel engine (compression

ignition), and gas turbine (continuous combustion). Diesel

compression-ignition engines are more fuel-efficient than gasoline engines

because compression ratios are higher,

and because the absence of air throttling improves

volumetric efficiency. Gasoline,

gas (natural gas,

propane), and diesel engines operate either on a four-stroke cycle

(Otto cycle) or a two-stroke cycle. Most gasoline engines are of

the four-stroke type, with operation as follows: (1) intake - piston moves

down the cylinder, drawing in a fuel-air mixture through the intake valve;

(2) compression - all valves closed, piston moves up, compressing the

fuel-air mixture, and spark ignites mixture near top of stroke; (3) power -

rapid expansion of hot combustion gases drives piston down, all valves

remain closed; (4) exhaust - exhaust valve opens and piston returns, forcing

out spent gases.

The diesel four-stroke cycle differs in that only air is

admitted on the intake stroke, fuel is injected at the top of the

compression stroke, and the fuel-air mixture is ignited by the heat of

compression rather than by an electric spark. The four-stroke-cycle engine

has certain advantages over a two-stroke, including higher piston speeds,

wider variation in speed and load, cooler pistons, no fuel lost through the

exhaust, and lower fuel consumption. l

The two-stroke cycle eliminates the intake and exhaust strokes of the

four-stroke cycle. As the piston ascends, it compresses the charge in the

cylinder, while simultaneously drawing a new fuel-air charge into the

crankcase, which is air-tight. (In the diesel two-stroke cycle, only air is

drawn in; the fuel is injected at the top of the compression stroke.) After

ignition, the piston descends on the power stroke, simultaneously

compressing the fresh charge in the crankcase. Toward the end of the power

stroke, intake ports in the piston skirt admit a new fuel-air charge that

sweeps exhaust products from the cylinder through exhaust ports; this means

of flushing out exhaust gases is called "scavenging". Because the crankcase

is needed to contain the intake charge, it cannot double as an oil

reservoir. Therefore, lubrication is generally supplied by oil that is

pre-mixed with the fuel. An important advantage of the two-stroke-cycle

engine is that it offers twice as many power strokes per cycle and, thus,

greater output for the same displacement and speed. Because two-stroke

engines are light in relation to their output, they are frequently used

where small engines are desirable, as in chain saws, outboard motors, and

lawn mowers. Many commercial, industrial, and railroad diesel engines are

also of the two-stroke type. l

Gas turbines differ from conventional internal combustion engines in that a

continuous stream of hot gases is directed at the blades of a rotor. A

compressor section supplies air to a combustion chamber into which fuel is

sprayed, maintaining continuous combustion. The resulting hot gases expand

through the turbine unit, turning the rotor and driveshaft.

Also see fuel injection,

turbine.

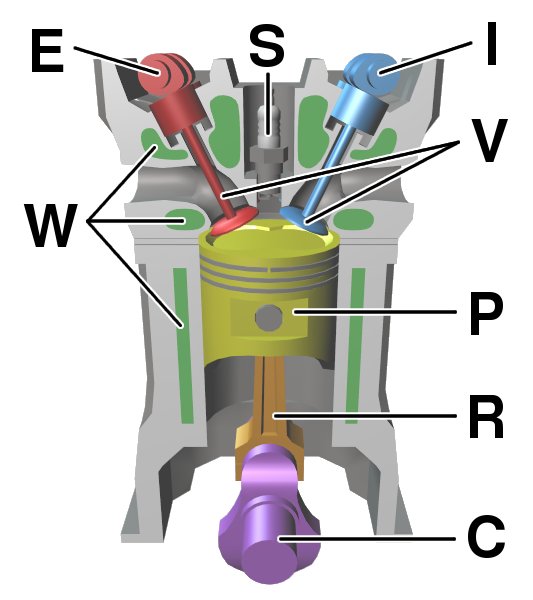

Components of a typical, four stroke cycle, internal

combustion piston engine.

E - Exhaust camshaft

I - Intake camshaft

S - Spark plug

V - Valves

P - Piston

R - Connecting rod

C - Crankshaft

W - Water jacket for coolant flow.