|

|

||

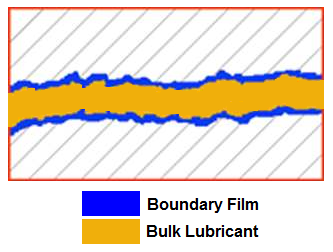

film lubrication

Such films can support the high contact stresses inherent in ball bearings Contact surface relative velocity, elastically formed footprint geometry, and fluid viscosity are prime determinants of EHD film thickness

Practical application of EHD theory involves the choice of Lubricating fluid properties (for example: viscosity at operating temperatures) and bearing internal design features consistent with the achievement of nearly complete asperity separation. This requires Film thickness in the order of four or more times greater than the average surface finish values of the ball and Also see: Boundary Lubrication and Mixed Film Lubrication. REAL Services 700 Portage Trail Cuyahoga Falls, OH 44221.3057 voice: 330.630.3700 fax: 330.630.3733 © 1995-2005 REAL Services® U.S.A. - Analytical Almanac All Rights Reserved |

||