is an

alloy used to

provide the bearing surface in a

plain bearing.

It was invented in 1839 by Isaac Babbitt in Taunton, MA. The term is used

today to describe a series of alloys used as a bearing metal. Babbitt metal

is characterized by its resistance to

galling.

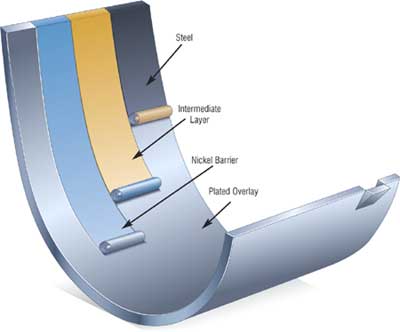

Originally used as a cast in place bulk bearing material, it is now more

commonly used as a thin surface layer in a complex, multi metal structure.

Common compositions for Babbitt alloys:

- 90% tin (Sn) - 10% copper (Cu)

- 89% tin (Sn) - 7% antimony (Sb) - 4% copper (Cu)

- 80% lead (Pb) - 15% antimony (Sb) - 5% tin (Sn)

Babbitt metal is soft and easily damaged, and seems at

first sight an unlikely candidate for a

journal bearing surface, but

this appearance is deceptive. The structure of the alloy is made up of small

hard crystals dispersed in a matrix of softer alloy. As the bearing wears

the harder crystal is exposed, with the matrix eroding somewhat to provide a

path for the lubricant between the high spots that provide the actual

bearing surface.